Tanzanite Ring

Tanzanite is a brittle gemstone. In this sculptural ring the tanzanite is well protected from harsh wear.

The design is an exercise in continuous line — a single length of gold swings up around and under itself where it embraces the stone.

The tanzanite has been prong set from the back. This allows the visible surface around the stone to be pre-polished, to be made with a feeling of thickness and substance, and to remain untouched during the actual setting.

The rectangular rod of 18 k. yellow gold.

The gold rod, mitered, bent, and soldered so as to create the square-ended shape that will eventually receive the stone.

Beginning to bend the sculptural shape of the ring. The rectangular cross-section of the rod was gradually cut back to nearly square in cross-section as the bending proceeded.

The tightest curves are now established.

The tanzanite is seen precisely fit into the ring from the back. Care is taken to accurately "seat" the upper edges of the stone so that they are flush to the metal without pressure points or without any effect of the stone "teeter-tottering."

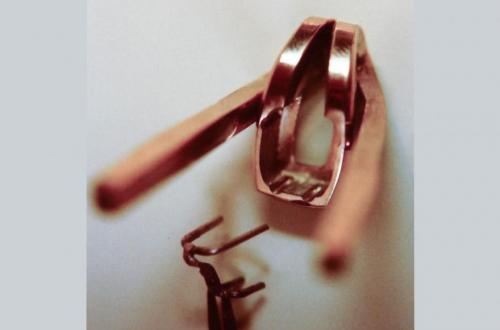

Within the back of the ring, four "troughs" are carved into the walls of the stone setting area. These will receive the four prongs. The prongs are constructed as a unit (shown in the tweezers). The tips of the four prongs are precisely soldered onto the "bottom" of each trough.

The four prongs are soldered in place and trimmed. The flat surface of each prong will be mitered just enough to accurately fold the prong down to the underside of the stone.

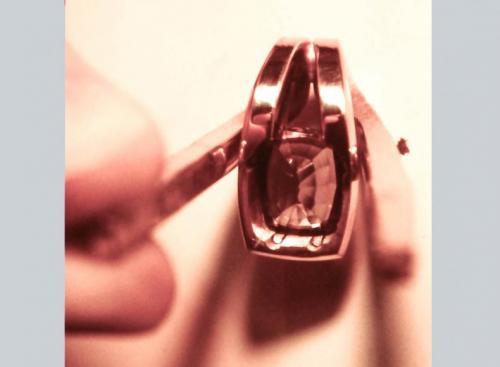

All the metal around the visible surfaces next to where the tanzanite will be set are pre-polished. The seat for the setting of a central diamond has been carved. The ring shank area under the finger has also been shaped, sized and joined (not visible in this photo).

The finished ring showing both stones set and the shaped ring shank. The area of setting around the diamond is smoothed and all surfaces are given their final polish.