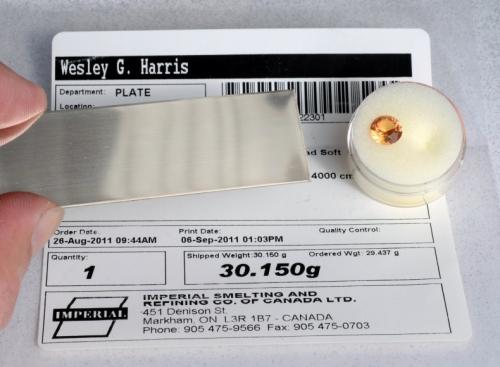

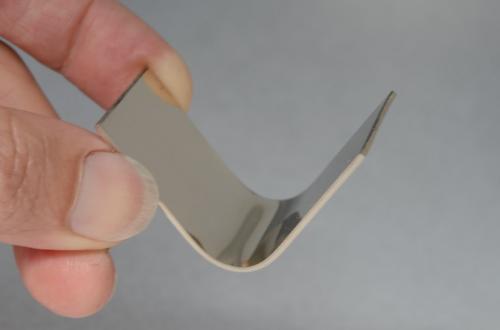

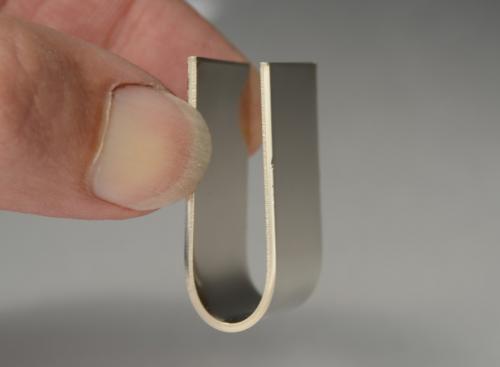

The design of this ring is an exercise in simplicity. A rectangular sheet of white gold is bent and joined at its ends. As seen along its edge, the shape becomes a slender tear-drop with two intersecting planes.

The design is also an exercise in fusion of form and function. As the planes merge, they taper to points at the very places where two prongs are required to secure the stone. There is a feeling of inherent logic in this kind of coincidence of form and function — a clarity and a feeling of synergy that simply pleases.

In this case, two prongs are the minimum. The underside of the synthetic corundum accurately seats into the metal below such that the prongs lock the stone in place.