Raw materials: 4 layers of pure copper, 3 layers of pure silver, and 1 layer of 22 k. yellow gold. All eight layers are perfectly flat and perfectly clean.

The fused stack. The layers were bolted between steel plates under hydraulic pressure. The assembly of bolted steel and mokume stack was embedded in charcoal inside a sealed stainless steel foil bag (to create a reducing or non-oxidizing atmosphere). The stainless steel bag and its contents were heated in a digital kiln for 14 hours at a temperature just below the melting point of any eutectic alloy between the layers (about 1400 degrees fahrenheit.). Under these conditions, molecular growth between the layers fuses the stack into a solid block.

The edges of the stack have been coated with solder, and the forging process has begun.

WIth repeated hammering and annealing, the stack is now about half of its original thickness.

The mokume stack forged out to a rectangular sheet about 6 mm. thick. The rectangle was cut along the black line to make the sheet closer to a square.

A spiral pattern is carved into the internal layers of the sheet.

The carved spiral pattern is hammered smooth, and the circular base of the bowl is established.

Additional pattern is carved and hammered smooth. Areas of de-lamination along the edges are trimmed off.

More pattern carved and (nearly) hammered smooth.

With most of the pattern established, the raising process begins.

At points of greatest stress, slight de-lamination occurred. These areas were repeatedly repaired with solder.

Approaching a bowl shape. Great care was taken while raising-in the valleys of the undulating edge.

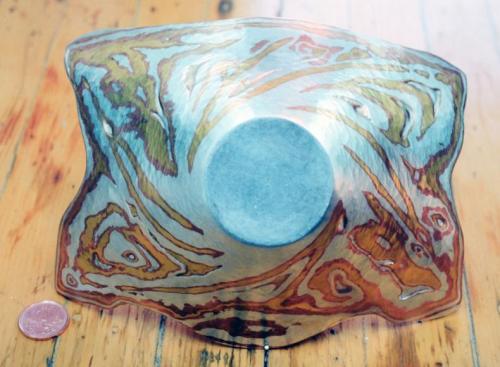

The finished Rose Bowl in 2003.

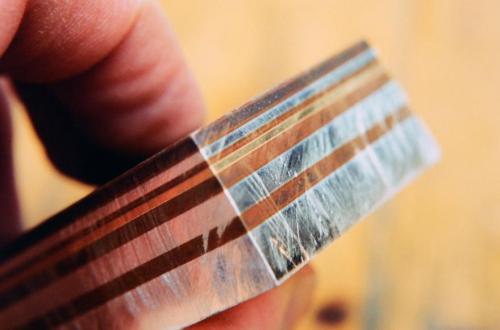

In 2010, I used the strip of mokume that had been cut from the original sheet to fashion a handle for the Rose Bowl. Here, a woodgrain pattern for the handle is being established.

The final shape and pattern of the handle. Additional layers of pure silver are soldered under the narrow end for strength and to create sufficient thickness for the stone setting. The sphalerite is also shown.

The sphalerite is set, and the area below the stone is contoured to a handle shape that will comfortably receive one's fingers. The area on the bowl that had been problematic due to de-lamination and cracking is now prepared to be overlapped by the handle. Holes for rivets are drilled in alignment through both the bowl and the handle.

The handle locked in place with wires that will be fashioned into rivets.

The finished 2010 version of the Rose Bowl showing the attached handle and the sphalerite.