The 100 oz. ingot of pure silver.

After approximately 10 "courses" of hammering and annealing (softening the metal by heating to a dull-red, then cooling).

After about 20 courses of hammering and annealing, gradually flowing the metal out like a pancake.

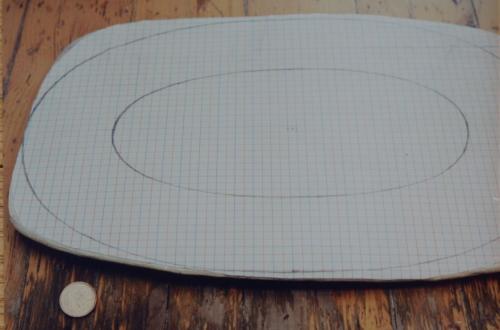

After a few more courses, the flattened sheet sheet is uniformly 4 mm. thick. An oval template is applied and the metal is trimmed to that outline.

With the base clamped flat, the sides of the bowl are raised by smithing. A slight mechanical advantage is achieved with each hammer blow, gradually constricting the circumference in upon itself (thickening), while each hammer blow also pinches the metal between steel tools (thinning).

Approximately 10 courses of raising. The hammer head used has a rounded-rectangular shape which causes directional flow of the metal. Starting each course at the base and systematically smithing the entire surface up to the rim, the metal flows most readily toward the remaining un-hammered (softer) metal.

About 20 courses of raising. The edge thickness at this stage is slightly less than 4 mm.

After a few more courses of raising, the surface is repeatedly planished ("ironed") using flat-faced hammers while the inside of the bowl conforms flush to steel anvil-like tools. This smoothes and hardens the metal. After repeated planishing, the final edge thickness is 3 mm. An undulating rim for the bowl is drawn in red (outside) and black (inside).

The rim of the bowl is trimmed. A 2 mm. wide recessed track has been carved directly into the edge of the bowl all around. An inlay of abalone shell is already set into the lower right area. Each sliver of shell is selected to match the undulating curve of the track, and each sliver is carved with a slightly beveled edge. The metal on either side of the track then bezel-sets the shell as the inlay proceeds.

A detail of the finished inlay. Each sliver of abalone shell ranges in length from between 1" to 2."