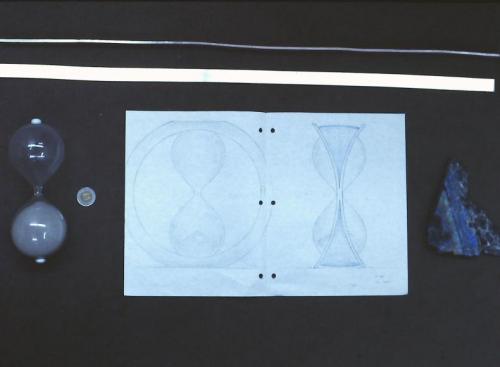

A drawing of the design and the main raw materials: two rectangular rods of sterling silver, the hour glass, and a sample slice of the multi-coloured labradorite.

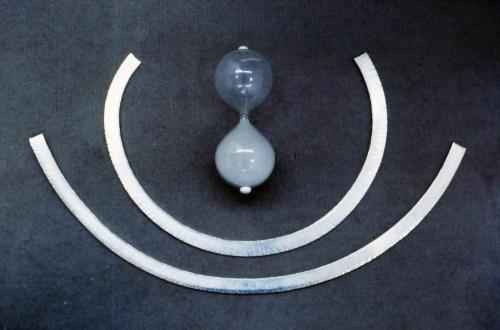

The two sterling rods are shown at different stages of being forged into circles. A cross-peen hammer is used with its rounded-rectangular hammer-head striking perpendicular to the length of the rod. The outer edge of the curve is hammered more than the inside edge thus pinching/flowing that edge more and causing the rod to steer in a curve.

One rod has been forged into a circle and the other is closing in. The hammer mark-off on the finished circle clearly shows how the outer edge of the metal has been worked the most.

The ends of the forged circles are lap-joined for strength. The join in the background has been soldered. The join in the foreground (not yet soldered) shows the overlapping ends and also shows the heads of two rivets that pre-lock and tighten the join in preparation to be soldered.

A wooden form has been made into which the circles will be pressed.

Using rubber mallets (or wooden or rawhide mallets), both circles have been uniformly pressed into the wooden form.

Recessed tracks are precisely carved into the inside surfaces of the shaped circles. These tracks will eventually receive and hold the edges of the labradorite arcs. Matching flat surfaces are also filed where the two framework halves will face together (these appear as shadowy half-circle areas in the photo).

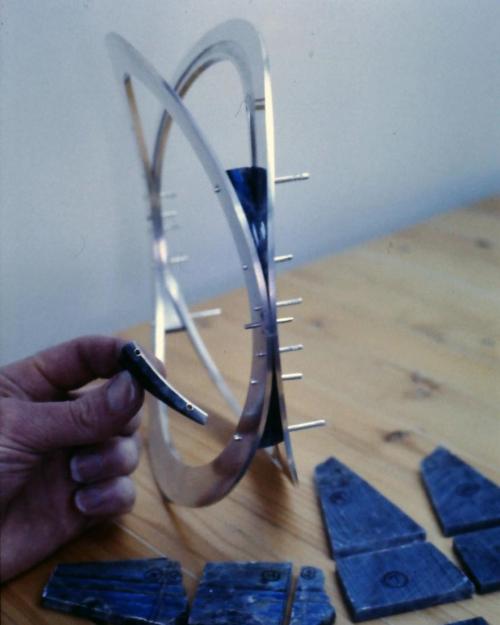

The two framework halves are shown temporarily locked in place with three rivet wires through each area of contact. The recessed tracks for the edge of the labradorite can be seen. The labradorite itself will be drilled and 28 rivet wires will eventually connect through the framework and the stones. 34 holes in the framework are already drilled, 28 of which are in the track.

This photo shows large slices of both varieties of labradorite. The blue labradorite in my hand is the parallel-lined crystalline structure called "twinning." The labradorite on the table is the multi-coloured variety from Tabor Island, Labrador, Canada. All the slices have been marked where they will be cut. A total of 12 panels of stone will be used (6 panels of each type) to create the two arcs.

All the panels of labradorite have been cut from the slices. The four narrowest pieces have been finished. The piece in my hand shows how the stone has been backed with sterling sheet for strength (labradorite would otherwise cleave or break too easily). Onto the sterling back have been soldered two brass tubes (these appear as little dark-centered circles in the example I am holding). These tubes will receive the rivet wires. The labradorite is carefully fit to the sterling backing with its tubes, then is epoxied to it which creates a strong and precise unit. The other three narrow labradorite units are seen temporarily locked into the framework with rivet wires.

All 12 panels of labradorite have been backed with sterling (with rivet tubes attached). They are seen here finished and temporarily locked into place by rivet wires. Final cutting and polishing of the curved labradorite surface was done with the panels epoxied end to end so as to create as seamless a contour as possible.

The multi-coloured variety of labradorite is seen in this photo. The remaining challenge was to fit and secure the sand-timer itself. Two sterling units were made with a yin-yang symbol in each. The ends of the sand-timer are fit under the yin-yang symbols, and each unit will be secured in place with two rivet wires. Two squares of labradorite have yet to be created (from the slices shown) to fit on either side of the yin-yang.

The "twinning" variety of labradorite is seen in this photo. Two squares of labradorite have yet to be created (from the slice I am holding) to fit on either side of the yin-yang.

This photo shows all the parts ready for final assembly. There are 34 rivet wires, four labradorite arcs, two units with yin-yang symbols, two halves of the sterling framework, and the hour glass sand-timer.

The finished piece showing the side with multi-coloured labradorite. All rivets have been set tightly to the surface of the framework, carefully filed flush and polished.